Nature has no wastes. Our cities however, are not designed on nature’s cycles, but on a straight path from mining/harvesting through use to disposal. Industrial ecology (sometimes referred to as eco-efficiency, industrial symbiosis, or eco-industrial planning) is the practice of reforming our community designs based on nature’s principles, such that “waste” energy and materials from one organization become resources for others.

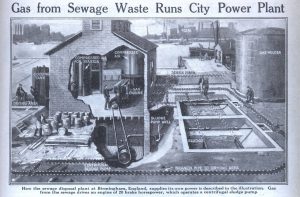

Industrial ecology is not new: in 300 BC the Romans built aqueducts to carry hot water to community baths. More modern examples of industrial ecology include using waste heat from factories to replace fossil fuels for heating communities, or converting municipal waste into biofuels. The fascinating thing about “closing the loops” of material or energy flows in industrial ecology is that two benefits always result: the impacts of disposal and harvesting of resources are reduced simultaneously.

Farallon’s work in this area is based on the principles of The Natural Step process, in which “waste” energy and materials from one organization become resources for others. Examples of industrial ecology include using waste heat from factories to replace fossil fuels for community energy systems, and converting source-separated municipal waste into clean biofuels. Our work also involves making recommendations for the advanced air pollution controls required to manage emissions from biofuels. Farallon is a member of the BC Hydro Alliance of Energy Professionals.

We also rely on international standards such as ISO 50001 for energy management systems, ISO 14040 for life-cycle assessments, and ISO 14064 for greenhouse gas inventories.

Farallon has developed proprietary computer-based engineering models to assess the performance of resource recovery facilities (capital, operating costs; inputs; outputs) including anaerobic digestion, gasification, various configurations of cogeneration, district energy, and energy recovery from waste heat sources. Farallon has also developed greenhouse gas modeling tools that incorporate emission factors and calculation methods based on the BC Reporting Regulation and Intergovernmental Panel on Climate Change protocols. Farallon has also developed a detailed database of energy conversion and pollution control technologies that includes equipment types, performance, lifespan, capital and operating costs, and physical space requirements, for equipment such as anaerobic digesters, gasifiers, cogeneration equipment, heat pumps, and adsorption chillers.

In addition to its technical aspects, our work involves extensive consultation and communications with stakeholders such as First Nations, Mayors and Councils, the public, local industry, environmental NGOs, utilities, and regulators.

“When we try to pick out anything by itself, we find it hitched to everything else in the universe.”

John Muir, (1892)

Founder of the American Sierra Club